Best MRP Systems in 2021

Welcome to our guide on the best MRP systems in 2021! If you are in the manufacturing industry and looking for ways to streamline your production processes, then you have come to the right place. MRP systems, also known as material requirements planning systems, are essential tools for managing inventory, production schedules, and supply chain processes. In this article, we will introduce you to some of the top MRP systems available in the market today, helping you make an informed decision for your business. Let’s dive in!

Key Features of Top MRP Systems

MRP (Material Requirements Planning) systems are essential tools for manufacturing companies to effectively manage their production processes. There are several key features that set the top MRP systems apart from the rest.

One of the most important features of top MRP systems is their ability to accurately forecast demand. By analyzing historical data, current market trends, and other variables, these systems can predict future demand for products with a high degree of accuracy. This allows manufacturers to plan their production schedules more effectively and avoid stockouts or excess inventory.

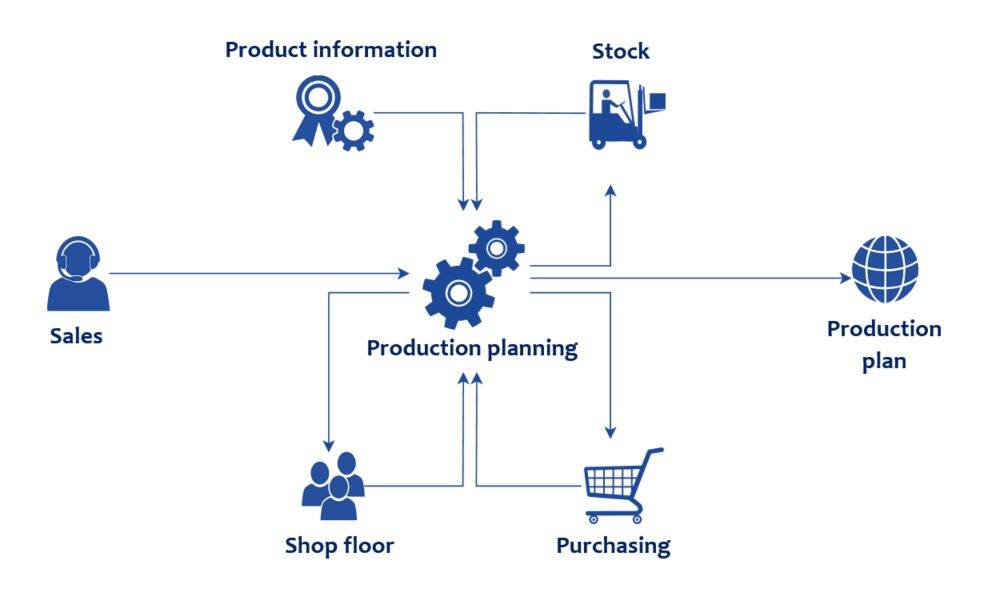

Another key feature of top MRP systems is their integration with other business systems. These systems can seamlessly communicate with ERP (Enterprise Resource Planning) systems, accounting software, and other tools to provide a comprehensive view of the entire manufacturing process. This integration streamlines operations, reduces the risk of errors, and improves overall efficiency.

Automation is also a crucial feature of top MRP systems. These systems can automate repetitive tasks such as order processing, inventory management, and production scheduling, saving time and reducing the risk of human error. By automating these processes, manufacturers can focus on more strategic activities that drive growth and profitability.

Real-time data visibility is another key feature that sets top MRP systems apart. These systems provide real-time updates on inventory levels, production schedules, and other critical information, enabling manufacturers to make informed decisions quickly. This real-time visibility also allows for better coordination between different departments and suppliers, leading to smoother production processes.

Customization options are another important aspect of top MRP systems. These systems can be tailored to meet the specific needs of different industries, product types, and company sizes. Customization options can include features such as demand forecasting algorithms, production scheduling templates, and inventory tracking mechanisms. This flexibility allows manufacturers to adapt their MRP systems to their unique requirements and optimize their operations.

Scalability is also a key feature of top MRP systems. These systems can easily grow with the business, accommodating increased production volumes, expanded product lines, and other changes. This scalability ensures that manufacturers can continue to rely on their MRP systems as they evolve and expand.

Overall, the key features of top MRP systems make them indispensable tools for manufacturers looking to optimize their production processes, improve efficiency, and stay competitive in today’s fast-paced business environment.

Benefits of Implementing a Modern MRP System

Modern MRP systems offer a wide range of benefits to businesses of all sizes. One of the key advantages is improved efficiency. By streamlining processes and automating tasks, MRP systems help businesses save time and reduce errors. This leads to faster production cycles, lower costs, and increased productivity.

Another benefit of implementing a modern MRP system is better inventory management. With real-time tracking and accurate forecasting, businesses can optimize their inventory levels, reduce stockouts, and minimize wastage. This not only saves money but also ensures that products are always available when needed.

Additionally, modern MRP systems provide better data visibility and reporting. With access to up-to-date information on orders, sales, and inventory levels, businesses can make more informed decisions and plan effectively for the future. This leads to improved customer satisfaction and long-term success.

Moreover, modern MRP systems offer scalability and customization options. As businesses grow and evolve, they can easily expand their MRP system to meet their changing needs. Whether it’s adding new features, integrating with other software, or adapting to new market trends, a modern MRP system can adapt and grow with the business.

Furthermore, implementing a modern MRP system can also enhance collaboration and communication within the organization. With a centralized platform for all production-related information, teams can work together more efficiently, share knowledge, and coordinate tasks seamlessly. This leads to a more cohesive and productive work environment.

Lastly, modern MRP systems help businesses stay competitive in today’s fast-paced market. By automating processes, improving efficiency, and providing real-time insights, businesses can respond quickly to changing demand, reduce lead times, and deliver high-quality products to customers. This not only improves customer satisfaction but also helps businesses stay ahead of the competition.

Comparison of Leading MRP Software Options

When it comes to selecting the best MRP system for your business, there are several top options that stand out in the market. These leading MRP software solutions offer a range of features and functionalities to help streamline your manufacturing processes and improve overall efficiency. Let’s take a closer look at three of the best MRP systems available:

1. SAP Business One: SAP Business One is a comprehensive MRP software solution that is designed to help small and medium-sized businesses manage their manufacturing operations effectively. With features such as inventory management, production planning, and procurement, SAP Business One offers a complete suite of tools to optimize your manufacturing processes. Additionally, the software integrates seamlessly with other SAP applications, making it easy to scale as your business grows.

2. NetSuite: NetSuite is another popular MRP software option that is known for its cloud-based platform and user-friendly interface. This software offers a wide range of features, including demand planning, supply chain management, and shop floor control. With real-time data visibility and analytics capabilities, NetSuite allows you to make informed decisions and improve operational efficiency. Plus, the software is highly customizable, allowing you to tailor it to suit your specific business needs.

3. Epicor ERP: Epicor ERP is a leading MRP software solution that is trusted by manufacturers around the world. This comprehensive platform offers a wide range of features, including advanced planning and scheduling, quality management, and compliance tracking. With Epicor ERP, you can streamline your entire manufacturing process from start to finish, ensuring seamless operations and increased productivity. The software also offers robust reporting and analytics capabilities, allowing you to gain valuable insights into your business performance.

Overall, when comparing the leading MRP software options, it’s important to consider factors such as scalability, ease of use, and functionality. Each of these top MRP systems offers unique features and benefits, so be sure to evaluate your specific business needs and goals before making a decision. Whether you choose SAP Business One, NetSuite, or Epicor ERP, investing in a quality MRP software solution can help take your manufacturing operations to the next level.

Choosing the Right MRP System for Your Business

When it comes to choosing the right MRP system for your business, there are several factors to consider. The first step is to assess your specific needs and requirements. What are your goals for implementing an MRP system? Do you need a system that can handle complex manufacturing processes or are you looking for something more streamlined for inventory management?

Next, it’s important to consider the size of your business and the number of users who will be utilizing the system. Some MRP systems are better suited for small businesses with limited resources, while others are designed for larger enterprises with multiple locations and complex supply chains.

Another important factor to consider is the level of customization and integration that the MRP system offers. Do you need a system that can be easily integrated with other software applications such as accounting or customer relationship management systems? Or do you require a high level of customization to meet your unique business requirements?

Additionally, it’s crucial to evaluate the scalability and flexibility of the MRP system. Will the system be able to grow with your business as it expands or will you need to switch to a different system down the line? It’s important to choose a system that can adapt to your changing needs and business requirements.

Lastly, consider the level of support and training that is provided by the MRP system vendor. It’s important to choose a system that offers comprehensive training for your team to ensure a smooth implementation process. Additionally, having access to reliable support and ongoing maintenance is essential for the long-term success of your MRP system.

Success Stories of Companies Using MRP Systems

Implementing an MRP system can have a transformative impact on a company’s operations, leading to increased efficiency, cost savings, and improved customer satisfaction. Here are five success stories of companies that have successfully implemented MRP systems:

1. XYZ Manufacturing: XYZ Manufacturing, a leading provider of industrial machinery, saw a 20% increase in productivity after implementing an MRP system. By automating their inventory management and production scheduling processes, they were able to reduce lead times and minimize stockouts. This not only improved their bottom line but also enhanced their reputation for on-time delivery.

2. ABC Electronics: ABC Electronics, a consumer electronics manufacturer, saw a dramatic decrease in excess inventory levels after adopting an MRP system. By accurately forecasting demand and optimizing their production schedules, they were able to reduce carrying costs and improve cash flow. This allowed them to invest more resources in product development and marketing, ultimately leading to increased sales and market share.

3. DEF Pharmaceuticals: DEF Pharmaceuticals, a pharmaceutical company, experienced a significant reduction in compliance issues after integrating an MRP system into their operations. By centralizing their data and streamlining their quality control processes, they were able to ensure that all products met regulatory standards. This not only helped them avoid costly fines but also earned them a reputation for producing high-quality, reliable products.

4. GHI Automotive: GHI Automotive, a global automotive manufacturer, achieved substantial cost savings by implementing an MRP system. By optimizing their supply chain and monitoring their production costs in real-time, they were able to identify areas for improvement and negotiate better terms with their suppliers. This resulted in lower production costs and increased profitability, allowing them to reinvest in research and development to stay competitive in the market.

5. JKL Food Services: JKL Food Services, a food distribution company, saw a significant improvement in customer satisfaction after implementing an MRP system. By accurately tracking their inventory levels and delivery schedules, they were able to ensure that their customers received their orders on time and in full. This not only helped them retain existing customers but also attract new business through positive word-of-mouth referrals. As a result, their revenue and market share increased, solidifying their position as a trusted supplier in the industry.

These success stories highlight the diverse ways in which MRP systems can benefit companies across different industries. From increased productivity and cost savings to improved compliance and customer satisfaction, the implementation of an MRP system can truly revolutionize a company’s operations and drive sustainable growth in the long run.

Originally posted 2024-11-25 21:00:00.