Closed-Loop MRP: Enhancing Efficiency and Value in Manufacturing

Welcome to the world of manufacturing efficiency and value enhancement with Closed-Loop MRP! In today’s competitive market, manufacturers are constantly seeking ways to streamline operations and maximize productivity. Closed-Loop MRP, also known as Material Requirements Planning, offers a solution to this challenge by integrating production, inventory, and supply chain management. By implementing this sophisticated system, manufacturers can reduce waste, optimize resources, and ultimately improve their bottom line. Let’s dive into how Closed-Loop MRP can revolutionize the manufacturing process!

What is Closed-Loop MRP?

Closed-Loop MRP, which stands for Material Requirements Planning, is a comprehensive system used by businesses to manage and control their manufacturing processes. It is a methodical approach that takes into account all the necessary components needed to produce a product, from raw materials to finished goods. The main goal of Closed-Loop MRP is to ensure that there are no shortages or excess inventory, allowing businesses to operate efficiently and cost-effectively.

One of the key features of Closed-Loop MRP is its ability to continuously monitor and update the production process in real-time. This means that as new orders are received or changes are made to existing orders, the system automatically adjusts the production schedule and inventory levels accordingly. By doing so, businesses can avoid delays in production, reduce lead times, and improve customer satisfaction.

Another important aspect of Closed-Loop MRP is its integration with other business functions such as finance, sales, and procurement. This allows for better coordination and communication between departments, leading to a more streamlined and cohesive operation. For example, when sales orders are input into the system, it immediately triggers the necessary production and procurement activities, ensuring that the right materials are available at the right time.

Moreover, Closed-Loop MRP also helps businesses optimize their resources and minimize waste. By accurately forecasting demand and inventory levels, companies can avoid overstocking on materials or producing more products than needed. This not only saves money but also reduces the environmental impact of excess production and waste.

In conclusion, Closed-Loop MRP is a powerful tool that enables businesses to efficiently manage their manufacturing processes from start to finish. By integrating all aspects of production, from planning to execution, businesses can improve their operational efficiency, reduce costs, and enhance customer satisfaction. It is a system that adapts to changing market conditions and helps businesses stay competitive in today’s fast-paced environment.

Benefits of Closed-Loop MRP

Closed-loop MRP offers several advantages for businesses looking to streamline their supply chain and production processes. One of the most significant benefits is improved accuracy in inventory management. By continuously updating and adjusting the MRP system based on real-time data, companies can reduce the risk of overstocking or stockouts, leading to cost savings and increased efficiency.

Another advantage of Closed-Loop MRP is enhanced communication and collaboration between different departments within an organization. With a centralized system that provides visibility into all aspects of the supply chain, teams can work together more effectively to coordinate production schedules, monitor inventory levels, and respond quickly to any changes in demand or supply.

Furthermore, Closed-Loop MRP can help businesses better track and analyze key performance indicators (KPIs) related to their production processes. By collecting data on production lead times, material usage, and on-time delivery rates, companies can identify areas for improvement and make data-driven decisions to optimize their operations.

In addition, Closed-Loop MRP enables businesses to more easily adapt to changes in market demand or supply chain disruptions. By providing real-time visibility into inventory levels and production capacity, companies can quickly adjust production schedules, reorder materials, or shift resources to meet changing customer needs or address unexpected challenges.

Moreover, Closed-Loop MRP can help businesses reduce waste and improve sustainability by optimizing production processes and minimizing excess inventory. By accurately forecasting demand, companies can produce the right amount of goods at the right time, reducing the need for storage space and minimizing the risk of obsolete or expired inventory.

Overall, Closed-Loop MRP offers a comprehensive solution for companies looking to streamline their operations, improve efficiency, and enhance their competitive advantage in today’s fast-paced and dynamic marketplace.

Implementation of Closed-Loop MRP

Implementing a Closed-Loop MRP system involves several key steps to ensure its successful integration within a company’s supply chain operations. First and foremost, it is essential to conduct a thorough analysis of the current production processes and workflows to identify areas that can benefit from the implementation of a Closed-Loop MRP system. This analysis will help determine the specific needs and requirements of the company, as well as highlight any potential challenges or obstacles that may arise during the implementation process.

Once the analysis is complete, the next step is to select a suitable Closed-Loop MRP system that aligns with the company’s goals and objectives. It is important to choose a system that is user-friendly, customizable, and scalable to accommodate future growth and changes within the organization. Additionally, the selected system should have the capability to integrate seamlessly with existing software and technologies to ensure a smooth transition and minimal disruption to daily operations.

After selecting a Closed-Loop MRP system, the next step is to implement the system within the company’s supply chain operations. This involves training employees on how to use the system effectively, setting up workflows and processes within the system, and defining key performance indicators to track and measure the system’s effectiveness. It is crucial to involve key stakeholders and decision-makers throughout the implementation process to ensure buy-in and support for the new system.

During the implementation phase, it is important to monitor and evaluate the system’s performance regularly to identify any issues or areas for improvement. This may involve conducting regular audits, collecting feedback from users, and analyzing data to measure the system’s impact on productivity, efficiency, and cost savings. By continuously monitoring the system and making necessary adjustments, companies can optimize their supply chain operations and maximize the benefits of implementing a Closed-Loop MRP system.

In conclusion, the implementation of a Closed-Loop MRP system is a strategic decision that can have a significant impact on a company’s supply chain operations. By following these key steps and best practices, companies can successfully integrate a Closed-Loop MRP system into their workflows and processes, leading to improved efficiency, productivity, and overall performance. With careful planning, communication, and collaboration, companies can unlock the full potential of a Closed-Loop MRP system and stay ahead of the competition in today’s fast-paced business environment.

Challenges in Closed-Loop MRP

Closed-loop MRP systems can offer numerous benefits to organizations, but they also come with their fair share of challenges. One of the main challenges in closed-loop MRP is data accuracy and consistency. In order for a closed-loop MRP system to function effectively, it requires accurate and up-to-date data on inventory levels, production schedules, and demand forecasts. However, many organizations struggle with siloed data and disparate systems, which can lead to inaccuracies and inconsistencies in the data being used by the MRP system.

Another challenge in closed-loop MRP is managing complexity. As organizations grow and expand their operations, the complexity of their supply chains also increases. This complexity can make it difficult to accurately plan and schedule production activities, leading to inefficiencies and delays in the manufacturing process. Additionally, the interconnected nature of closed-loop MRP systems means that changes in one part of the system can have ripple effects throughout the entire supply chain, further complicating the planning and scheduling process.

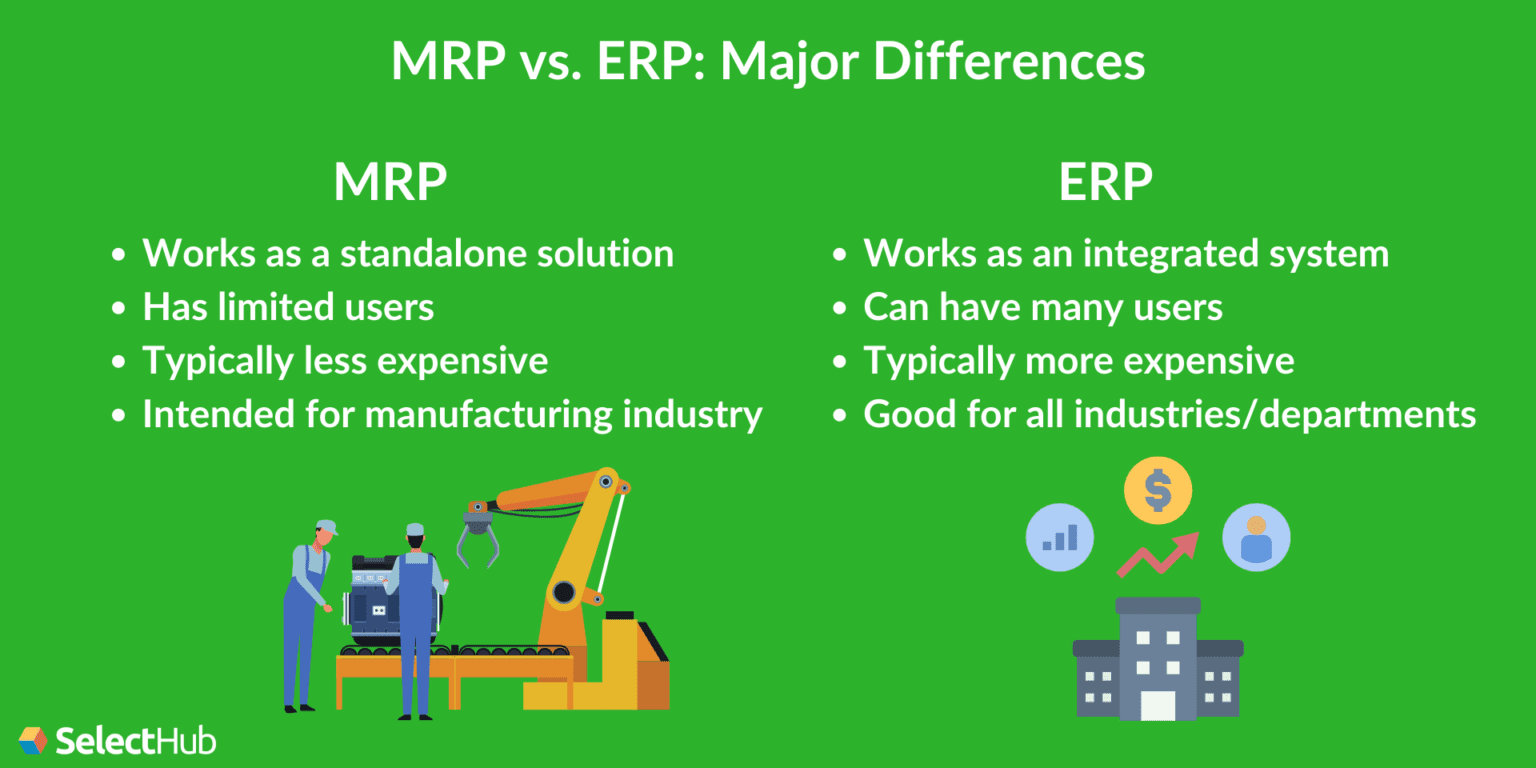

Integration is another challenge in closed-loop MRP. In order for a closed-loop MRP system to be effective, it needs to be tightly integrated with other systems, such as ERP systems, CRM systems, and business intelligence tools. However, many organizations struggle with integration issues, as different systems may use different data formats or operate on different platforms. This can lead to data synchronization issues and make it difficult for organizations to get a holistic view of their operations.

Lastly, one of the biggest challenges in closed-loop MRP is change management. Implementing a closed-loop MRP system requires significant changes to an organization’s processes, workflows, and culture. This can be met with resistance from employees who are accustomed to working in a certain way or who may be skeptical of the benefits of the new system. Additionally, implementing a closed-loop MRP system can be a time-consuming and resource-intensive process, requiring significant investments in training and support.

Future of Closed-Loop MRP

Closed-loop MRP is a dynamic and evolving system that has the potential to revolutionize the way businesses manage their manufacturing processes. As technology continues to advance at a rapid pace, we can expect to see even more sophisticated closed-loop MRP systems emerge in the future. These systems will be able to analyze and predict supply chain disruptions with greater accuracy, allowing businesses to proactively address issues before they impact production.

One of the key trends that we can expect to see in the future of closed-loop MRP is the integration of artificial intelligence and machine learning algorithms. These technologies will enable MRP systems to learn from past data and continuously improve their predictive capabilities. By leveraging AI and machine learning, closed-loop MRP systems will be able to make more accurate forecasts and recommendations, helping businesses optimize their production processes and reduce waste.

Another exciting development on the horizon for closed-loop MRP is the integration of IoT devices and sensors into the system. These devices will provide real-time data on inventory levels, production rates, and machine performance, allowing MRP systems to make more informed decisions and adjustments on the fly. By harnessing the power of IoT, closed-loop MRP systems will become even more agile and responsive to changes in the manufacturing environment.

Furthermore, we can expect to see increased collaboration and integration between closed-loop MRP systems and other business functions, such as finance, sales, and marketing. By breaking down silos between departments and sharing data across the organization, businesses can achieve greater transparency and alignment in their operations. This cross-functional integration will enable closed-loop MRP systems to make more holistic and strategic decisions that drive overall business performance.

Lastly, the future of closed-loop MRP will likely involve greater customization and personalization to meet the unique needs of individual businesses. As technology advances and becomes more accessible, businesses will have the opportunity to tailor their MRP systems to fit their specific industry, product, and supply chain requirements. This level of customization will empower businesses to stay competitive in a rapidly changing market and drive innovation in their manufacturing processes.

Originally posted 2024-11-29 13:00:00.