Hey there, small business owner! Are you looking for ways to streamline your operations and boost efficiency? Look no further than MRP systems. These powerful tools can help small businesses manage their resources, track inventory, and improve production planning. In this article, we will explore how small businesses can benefit from implementing MRP systems and take their operations to the next level.

Benefits of Implementing MRP in Small Businesses

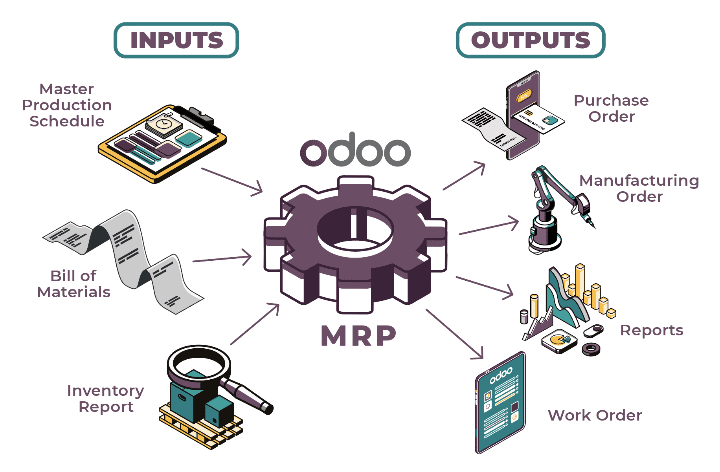

MRP, or Material Requirements Planning, is a system that helps small businesses manage their inventory, production schedule, and purchasing activities more efficiently. By implementing MRP in a small business, owners can enjoy a wide range of benefits that can ultimately lead to increased productivity and profitability. Here are some of the key advantages of using MRP in a small business:

1. Enhanced Inventory Management: One of the most significant benefits of implementing MRP in a small business is the improved inventory management it offers. With MRP, businesses can create accurate and up-to-date inventory reports that help them track the availability of raw materials and finished goods in real-time. This helps small business owners avoid overstocking or understocking issues, ensuring that they have the right amount of inventory on hand to meet customer demand without tying up excess capital.

Furthermore, MRP helps small businesses optimize their inventory levels by predicting future demand based on historical data and current market trends. By having a clear understanding of their inventory needs, small businesses can minimize stockouts, reduce carrying costs, and improve overall efficiency in their operations.

Additionally, MRP allows small businesses to establish reorder points and lead times for each item in their inventory, which helps streamline the purchasing process and ensures that they always have the right materials on hand when needed. This level of control over inventory management can lead to cost savings, improved customer satisfaction, and increased competitiveness in the market.

Overall, the enhanced inventory management capabilities provided by MRP can help small businesses reduce wastage, minimize stock obsolescence, and improve cash flow by optimizing their inventory levels. By having the right materials in the right quantities at the right time, small businesses can operate more efficiently and effectively, which can have a positive impact on their bottom line.

Common Challenges and Solutions for Small Businesses Implementing MRP

Implementing Material Requirements Planning (MRP) systems can be a daunting task for small businesses due to various challenges they may face. Let’s take a look at some of the common challenges and solutions for small businesses implementing MRP:

1. Limited Resources: One of the biggest challenges small businesses face when implementing MRP is limited resources. Small businesses may not have the manpower or budget to dedicate to a full-scale MRP implementation. This can lead to delays in implementation and inefficiencies in the processes.

Solution: One solution to this challenge is to start small and prioritize the most critical aspects of the MRP system. Small businesses can focus on implementing the core functionalities of MRP that will provide the most immediate benefits. They can also consider outsourcing certain tasks to third-party service providers who specialize in MRP implementation.

2. Resistance to Change: Another common challenge small businesses face when implementing MRP is resistance to change from employees. Employees may be accustomed to manual processes or legacy systems and may be hesitant to adopt new technologies.

Solution: To address this challenge, small businesses can involve employees in the implementation process from the beginning. Providing proper training and support to employees can help them understand the benefits of MRP and ease their transition to the new system. It is also important for management to communicate the reasons for implementing MRP and the positive impact it will have on the business.

3. Data Accuracy: Small businesses often struggle with maintaining accurate and up-to-date data for their MRP systems. Inaccurate data can lead to errors in production planning, inventory management, and order fulfillment.

Solution: To overcome this challenge, small businesses should invest in data management tools and processes to ensure data accuracy. Implementing regular data audits and training employees on data entry best practices can help improve the quality of data in the MRP system. It is also important to integrate the MRP system with other business systems to streamline data entry processes and minimize errors.

4. Scalability: As small businesses grow, they may face challenges in scaling their MRP systems to accommodate increased production volume and complexity. Traditional MRP systems may not be flexible enough to adapt to changing business requirements.

Solution: Small businesses can address scalability issues by choosing a cloud-based MRP system that can easily scale to meet growing business needs. Cloud-based MRP systems offer flexibility and scalability, allowing small businesses to add new users, expand storage capacity, and customize features as needed. This ensures that the MRP system can grow with the business and support future expansion.

By understanding and addressing these common challenges, small businesses can successfully implement MRP systems and realize the benefits of improved efficiency, reduced costs, and increased productivity.

How MRP Can Improve Efficiency and Customer Satisfaction in Small Businesses

MRP, or Materials Requirements Planning, is a system that helps small businesses manage their inventory, production, and scheduling processes more effectively. By implementing an MRP system, small businesses can streamline their operations, reduce costs, and improve overall efficiency. Here are three ways in which MRP can improve efficiency and customer satisfaction in small businesses:

1. Better Inventory Management

One of the key benefits of using an MRP system is that it helps small businesses keep track of their inventory levels more accurately. By analyzing historical data and forecasting future demand, MRP software can help businesses determine the optimal levels of inventory to maintain. This can help prevent stockouts and overstock situations, which can lead to lost sales and increased carrying costs. With better inventory management, small businesses can ensure that they always have the right products in stock to meet customer demand, leading to increased customer satisfaction.

2. Improved Production Planning

MRP systems also help small businesses improve their production planning processes. By taking into account lead times, production capacities, and material availability, MRP software can generate accurate production schedules that optimize resources and minimize production bottlenecks. This results in smoother production processes, shorter lead times, and faster order fulfillment. With improved production planning, small businesses can deliver orders to customers more quickly and efficiently, leading to higher customer satisfaction levels.

3. Enhanced Customer Communication

Another way in which MRP can improve efficiency and customer satisfaction in small businesses is by enhancing communication with customers. MRP systems provide real-time visibility into production schedules, inventory levels, and order statuses, allowing small businesses to provide customers with accurate and up-to-date information about their orders. This transparency not only helps build trust and loyalty with customers but also allows businesses to proactively address any issues or delays that may arise. By keeping customers informed every step of the way, small businesses can ensure a positive experience and increase customer satisfaction.

In conclusion, implementing an MRP system can have a significant impact on the efficiency and customer satisfaction of small businesses. By improving inventory management, production planning, and customer communication, MRP software can help small businesses operate more effectively and meet customer expectations more consistently. As small businesses continue to face competition and pressure to deliver products quickly and accurately, investing in an MRP system can be a strategic decision that pays off in the long run.

Choosing the Right MRP System for Your Small Business

When looking for the right MRP system for your small business, there are a few important factors to consider. The first step is to determine your specific needs and requirements. Consider the size of your business, the complexity of your production process, and the number of users who will need access to the system. This will help you narrow down your options and choose a system that is best suited to meet your business needs.

Another important factor to consider when choosing an MRP system is the ease of use. Many small businesses do not have dedicated IT staff, so it is important to choose a system that is user-friendly and easy to learn. Look for a system that offers training and support to help you and your employees get up to speed quickly.

Integration with other systems is also important when choosing an MRP system for your small business. Make sure that the system you choose is compatible with any existing software or systems that you are using. This will help streamline your operations and ensure that all of your systems work seamlessly together.

Cost is another factor to consider when choosing an MRP system for your small business. While cost should not be the only consideration, it is important to choose a system that fits within your budget. Look for a system that offers a good value for the features it provides, and consider any additional costs such as training, support, and maintenance.

Finally, consider the scalability of the MRP system you choose. While your business may be small now, it is important to choose a system that can grow with your business. Look for a system that offers additional features and capabilities that you can add as your business expands. This will help ensure that your MRP system continues to meet your needs as your business grows.

Tips for Successful MRP Implementation in Small Businesses

Implementing a Material Requirements Planning (MRP) system in a small business can be a daunting task, but with the right approach and strategies, it can lead to increased efficiency, reduced costs, and overall improved operations. Here are some tips to help small businesses successfully implement MRP:

1. Start with a Clear Implementation Strategy: Before diving into MRP implementation, it is crucial to have a well-defined strategy in place. This includes setting clear objectives, timelines, and budget for the implementation process. Consider involving key stakeholders in the planning phase to ensure buy-in and support throughout the implementation.

2. Invest in Employee Training: One of the key factors for successful MRP implementation is ensuring that employees are well-trained on how to effectively use the system. Provide comprehensive training sessions for all staff members who will be using the MRP system, and consider offering refresher courses to ensure ongoing proficiency.

3. Data Accuracy is Key: The success of an MRP system heavily relies on the accuracy of the data inputted into the system. Make sure to clean up and organize your existing data before implementing the MRP system, and establish processes for maintaining data accuracy moving forward. Regularly review and update data to ensure the system is functioning optimally.

4. Collaborate with Suppliers and Vendors: Effective communication with suppliers and vendors is crucial for successful MRP implementation. Work together to establish clear expectations, lead times, and inventory requirements to streamline the supply chain process. Encouraging collaboration and partnership will help mitigate potential disruptions and ensure a smooth MRP implementation process.

5. Monitor and Evaluate Performance: Once the MRP system is up and running, it is important to continuously monitor and evaluate its performance. Establish key performance indicators (KPIs) to track metrics such as inventory turnover, on-time delivery rates, and cost savings. Regularly review these KPIs and make adjustments as needed to ensure the MRP system is meeting its objectives.

By following these tips for successful MRP implementation in small businesses, companies can maximize the benefits of the system and improve overall operational efficiency. With careful planning, investment in employee training, emphasis on data accuracy, collaboration with suppliers, and ongoing performance monitoring, small businesses can successfully implement MRP and optimize their operations for long-term success.

Originally posted 2024-11-28 06:00:00.