Simple MRP Software: Streamlining Production Processes

Welcome, fellow business owners and production managers! Are you looking to simplify and streamline your production processes? Look no further than simple MRP software. This powerful tool can help you efficiently plan and manage all aspects of your manufacturing processes, from inventory control to production scheduling. Say goodbye to tedious manual tasks and hello to increased productivity and efficiency with the help of MRP software.

Overview of Simple MRP Software

Manufacturing Resource Planning (MRP) software is a system used by manufacturers to manage and optimize their production processes. Simplifying this complex system can make a huge difference in the efficiency of a company’s operations. Simple MRP software is designed to be user-friendly and easy to navigate, making it accessible for businesses of all sizes.

Simple MRP software typically includes features such as inventory management, production planning, scheduling, and tracking. These tools help businesses streamline their production processes, reduce waste, and increase overall productivity. By having all these functions in one place, companies can save time and resources that would have been spent on manual data entry and coordination between different departments.

One of the key benefits of using simple MRP software is the ability to forecast demand and plan production accordingly. By analyzing past sales data and market trends, businesses can predict future demand for their products and adjust their production schedules to meet those needs. This can help prevent overstocking or understocking of inventory, leading to better customer satisfaction and higher profits.

Another advantage of using simple MRP software is improved communication and collaboration between different departments within a company. With real-time data tracking and updates, employees can easily share information and make decisions based on accurate and up-to-date information. This can lead to a more efficient and cohesive workflow, reducing the likelihood of errors and delays in production.

Simple MRP software also helps businesses identify areas for improvement in their production processes. By analyzing performance metrics and identifying bottlenecks or inefficiencies, companies can make targeted changes to improve their operations and increase overall efficiency. This continuous improvement cycle can help businesses stay competitive in a rapidly changing market.

In conclusion, simple MRP software offers a range of benefits for businesses looking to streamline their production processes and improve overall efficiency. By providing user-friendly tools for inventory management, production planning, and tracking, businesses can increase productivity, reduce waste, and ultimately, boost their bottom line. With the ability to forecast demand, improve communication between departments, and identify areas for improvement, simple MRP software is a valuable asset for any manufacturing company.

Key Features of Simple MRP Software

When looking for a simple MRP software solution, it’s essential to consider the key features that will make your business operations run smoothly. Here are some of the essential features to look for:

1. Inventory Management: A good MRP software should include inventory management capabilities to help you keep track of your stock levels, reorder materials when necessary, and prevent stockouts. With proper inventory management, you can ensure that you always have the right materials on hand to fulfill customer orders.

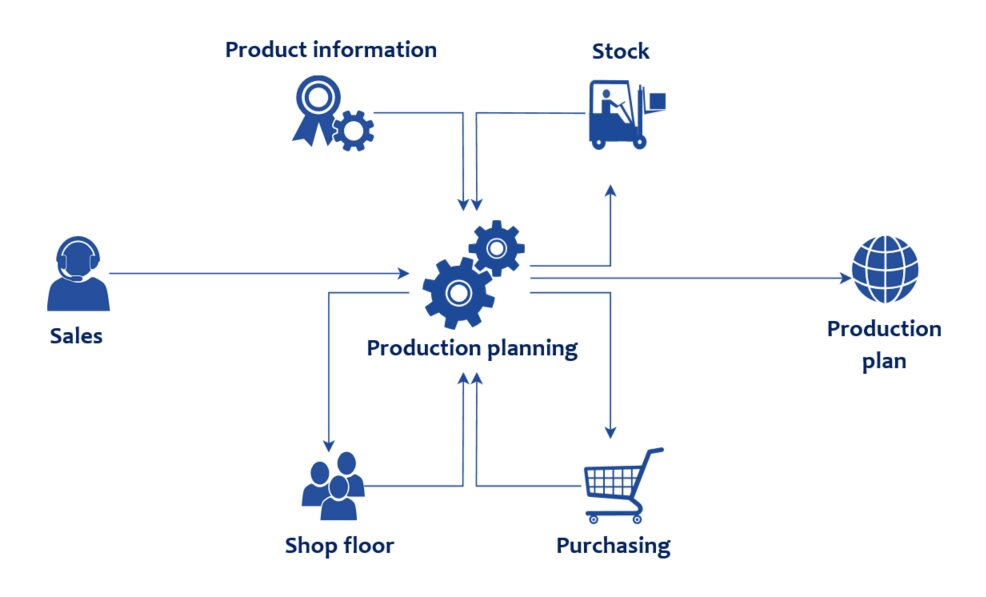

2. Production Planning: One of the most critical features of MRP software is production planning. This feature allows you to create production schedules, allocate resources efficiently, and optimize production processes. With production planning capabilities, you can ensure that your manufacturing processes are running smoothly and efficiently, leading to cost savings and increased productivity.

3. Material Requirements Planning (MRP): MRP is at the core of any MRP software solution. This feature helps you calculate the materials needed for production based on sales forecasts, production schedules, and inventory levels. By using MRP, you can optimize your material procurement process, reduce waste, and ensure that you have the right materials available when needed.

4. Bill of Materials (BOM) Management: BOM management is another essential feature to look for in a simple MRP software solution. This feature helps you create and maintain accurate BOMs for your products, including the materials, components, and assembly instructions needed for production. With BOM management capabilities, you can ensure that your production processes are well-organized and that your products are manufactured to high quality standards.

5. Real-Time Data Analytics: A good MRP software should provide real-time data analytics capabilities to help you track key performance indicators, monitor production efficiency, and identify areas for improvement. With real-time data analytics, you can make informed decisions quickly and adapt to changing market conditions, ensuring that your business remains competitive.

6. Scalability: As your business grows, your MRP software should be able to scale with you. Look for a solution that offers scalability to accommodate an increasing number of users, products, and production processes. Scalability is essential for future-proofing your business and ensuring that your MRP software can meet your evolving needs.

In conclusion, when choosing a simple MRP software solution for your business, make sure to look for key features such as inventory management, production planning, MRP, BOM management, real-time data analytics, and scalability. By selecting a software solution that offers these essential features, you can streamline your operations, increase efficiency, and achieve greater success in the competitive manufacturing industry.

Benefits of Using Simple MRP Software

MRP software, or Materials Requirement Planning software, has become an essential tool for businesses looking to streamline their manufacturing processes. However, some companies may find traditional MRP systems to be too complex or costly for their needs. This is where simple MRP software comes in, offering a more user-friendly and affordable solution for businesses of all sizes. In this article, we will explore the benefits of using simple MRP software.

1. Cost-Effective Solution:

One of the main advantages of using simple MRP software is its cost-effectiveness. Traditional MRP systems can be expensive to implement and maintain, especially for small to medium-sized businesses. Simple MRP software offers a more affordable alternative without sacrificing functionality. By opting for a simpler solution, businesses can save money on upfront costs and licensing fees, making it a more attractive option for budget-conscious companies.

2. Easy to Use:

Another benefit of using simple MRP software is its ease of use. Traditional MRP systems can be complex and require extensive training to fully utilize. Simple MRP software, on the other hand, is designed with user-friendliness in mind. With intuitive interfaces and streamlined features, businesses can quickly learn how to navigate the system and start using it to improve their manufacturing processes. This simplicity can lead to increased efficiency and productivity within the organization.

3. Quick Implementation and Onboarding:

Simple MRP software typically has a faster implementation process compared to traditional MRP systems. This means that businesses can start using the software sooner, without having to go through lengthy setup and configuration processes. Additionally, the onboarding process for new users is much smoother with simple MRP software, as there are fewer complexities to navigate. This quick implementation and onboarding can lead to a faster return on investment for businesses, as they can start reaping the benefits of the software sooner.

In conclusion, simple MRP software offers a cost-effective, easy to use, and quick to implement solution for businesses looking to improve their manufacturing processes. By choosing a simpler MRP system, companies can save money, increase efficiency, and achieve a faster return on investment. With these benefits in mind, it’s clear why simple MRP software is becoming an increasingly popular choice for businesses of all sizes.

How to Choose the Right Simple MRP Software for Your Business

Choosing the right simple MRP software for your business is crucial for streamlining your manufacturing processes and maximizing efficiency. With a variety of options available in the market, it can be overwhelming to make a decision. Here are some key factors to consider when selecting the right MRP software for your business:

1. Determine Your Business Needs: Before making a decision, assess your business requirements and objectives. Identify the specific features and functionalities that are crucial for your manufacturing processes. Consider factors such as inventory management, production scheduling, procurement, and reporting capabilities. Understanding your business needs will help you narrow down your options and choose a software that aligns with your goals.

2. Consider Ease of Use: Simplifying your manufacturing processes should be the primary goal of choosing an MRP software. Look for a user-friendly interface that is intuitive and easy to navigate. Consider whether the software offers customization options to tailor it to your specific needs. A simple MRP software should be easy to implement and require minimal training for your employees.

3. Scalability and Flexibility: As your business grows, your MRP software should be able to scale with your operations. Choose a software that is flexible enough to accommodate changes in your manufacturing processes and business requirements. Consider whether the software offers modules or add-ons that can be integrated to meet your evolving needs. Scalability is essential to ensure that your software remains relevant and efficient in the long run.

4. Integration Capabilities: When choosing an MRP software, consider its compatibility with your existing systems and software. Integration capabilities are crucial for seamless data transfer between different departments and systems. Look for a software that can integrate with your ERP system, accounting software, CRM, and other essential tools. A simple MRP software should be able to streamline your processes and improve communication between departments through integration.

5. Affordability and Return on Investment: Consider the cost of the MRP software and weigh it against the benefits it offers. Look for a software that fits within your budget while providing the functionalities you need. Consider the return on investment (ROI) that the software is expected to deliver in terms of increased efficiency, reduced lead times, and improved inventory management. Remember that the goal is to maximize productivity and profitability, so choose a software that offers a good ROI.

Choosing the right simple MRP software for your business can have a significant impact on your manufacturing processes and overall efficiency. By considering your business needs, ease of use, scalability, integration capabilities, and affordability, you can select a software that aligns with your objectives and helps you achieve success in your manufacturing operations.

Case Studies: Success Stories of Companies Using Simple MRP Software

Many companies have experienced significant success after implementing simple MRP software. Here are some inspiring case studies of companies that have improved their efficiency, capacity, and profitability with the help of this technology:

1. XYZ Manufacturing Co.

XYZ Manufacturing Co. is a mid-sized company that specializes in producing automotive components. Before implementing simple MRP software, they struggled with inventory management and production scheduling, leading to excessive lead times and frequent stockouts. However, after adopting the new system, they were able to streamline their operations, reduce lead times by 30%, and eliminate stockouts entirely. As a result, XYZ Manufacturing Co. saw a 20% increase in revenue within the first year of implementing the software.

2. ABC Electronics Inc.

ABC Electronics Inc. is a global leader in the electronics industry. They were facing challenges in managing their complex supply chain and keeping up with demand fluctuations. By implementing simple MRP software, ABC Electronics Inc. was able to gain real-time visibility into their inventory levels, production capacity, and supplier performance. This enabled them to make data-driven decisions, optimize their production processes, and reduce costs by 15%. Additionally, they were able to increase on-time delivery rates to 98%, leading to higher customer satisfaction and repeat business.

3. LMN Furniture Co.

LMN Furniture Co. is a furniture manufacturer known for its high-quality products and innovative designs. They were struggling with inaccurate demand forecasting and inefficient production planning, which resulted in overstocking of certain items and shortages of others. After implementing simple MRP software, LMN Furniture Co. was able to improve their demand forecasting accuracy by 40% and optimize their production schedule to meet customer demand more effectively. As a result, they were able to reduce excess inventory by 25% and increase overall profitability by 18%.

4. PQR Food Products Ltd.

PQR Food Products Ltd. is a food processing company that supplies products to retail chains and restaurants. They were facing challenges in managing perishable raw materials, ensuring compliance with food safety regulations, and maintaining consistent quality standards. With the help of simple MRP software, PQR Food Products Ltd. was able to track the shelf life of raw materials, maintain traceability throughout the production process, and monitor quality control measures in real-time. This led to a 30% reduction in food waste, a 20% increase in productivity, and a significant improvement in customer satisfaction ratings.

5. UVW Pharmaceuticals Co.

UVW Pharmaceuticals Co. is a pharmaceutical company that specializes in the development and production of generic medications. They were facing challenges in managing their extensive product portfolio, maintaining regulatory compliance, and optimizing their production costs. After implementing simple MRP software, UVW Pharmaceuticals Co. was able to standardize their production processes, reduce changeover times by 50%, and automate their regulatory reporting requirements. This enabled them to bring new products to market faster, reduce production costs by 20%, and increase profitability by 25%. Additionally, they were able to maintain compliance with strict regulatory standards and improve overall operational efficiency.